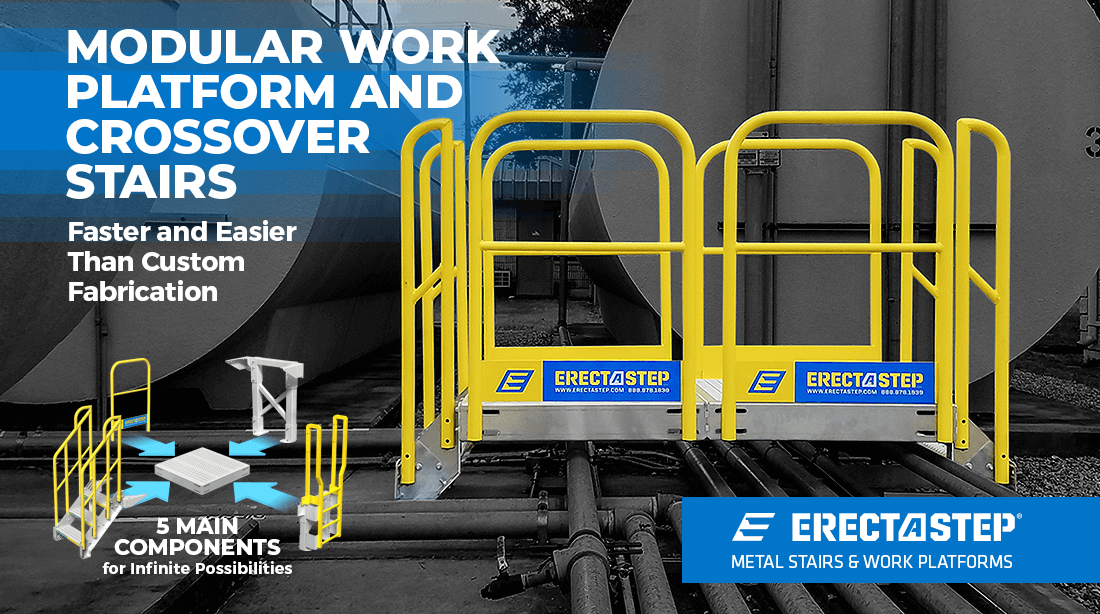

Adding to a growing list of over 24 innovative proprietary industrial designs, SixAxis, LLC secured U.S. patent 10,358,871 in July of this year on behalf of its ErectaStep brand. The product line is ingeniously simple, composed of 5 OSHA compliant modular components designed with an infinite number of possible configurations to provide safe and efficient access to workers in industrial settings.

ErectaStep components include a universal platform, safety stairs, handrails, ladder, and tower support. Crossovers and work platforms can be configured for use by workers in any industrial setting. All components are OSHA compliant, in stock, and ready to ship. Plant managers work with a sales rep to create a custom configuration on-site and in most cases, the components can be ordered and shipped the same day.

“Now that the patent is on the books, we can focus on helping customers understand the huge difference between ErectaStep and anything else on the market,” explains co-founder and CEO of SixAxis and ErectaStep, Rob Honeycutt.

“We’re not just manufacturing equipment. We’ve created a fundamental shift in how our customers stay OSHA compliant.” Prior to ErectaStep, applying standard solutions or custom fabrication were the only options available. “Our customers no longer have to sacrifice safety or efficiency to get the job done. The limitless configurations and immediate availability of ErectaStep solutions shave significant time and cost off of every application.”

Stand-out solution

Honeycutt explains how ErectaStep safety solutions differ from others on the market: “Critical steps were taken to focus on important details such as the dimensions of the stairs and handrails so they wouldn’t interfere with platform handrails. We imagined every possible worst-case scenario so that customers in any industry can use our solutions to keep their workers safe and their facilities productive.”

ErectaStep, named after the metal toy Erector Sets Honeycutt played with as a child, is made up of robotically welded components manufactured on the assembly line at SixAxis’ facility in Andrews, SC. The 3’ x 3’ platforms have a universal hole pattern on all four sides which allows them to be bolted together in any direction.

“The best part about this feature,” explains Honeycutt, “is that when a new product is added to the line or changes are made to the production process, ErectaStep components can be taken apart and reassembled to meet the changing needs of the facility. These are not one-time use solutions. They’ll remain useful much longer than anything else on the market.” Another unusual feature included in the patent is the unique ability to extend up to three platforms without additional support. “This is a game-changer for production facilities looking to provide safe clearance and access in challenging spaces.

ErectaStep platforms are created from a single, continuous piece of sheet metal that is cut and folded to form the shape. The pre-engineered components meet or exceed all OSHA standards. Easily installed with no need for special tools, customers will save time and money on a valuable and safe solution.

SixAxis has been providing access and safety systems to the truck, rail, ship, aviation, and aerospace industries using state-of-the-art technology since 2003. Their award-winning products and patents are created under brands such as SafeRack, ErectaStep, YellowGate, Rollastep, and Aerostep and have helped support the efforts of industry-leading Fortune 500 companies such as Boeing, Dow, and Coca-Cola to name just a few.

For more information visit www.erectastep.com and www.sixaxisllc.com